Bobcat S185 skid steer loader prides itself on helping users tackle challenging tasks daily. The loader delivers more than the average lifting capacity thanks to its powerful engine and high-flow hydraulics.

You can use it in various applications, particularly in the farming and construction industries. But like other heavy machinery, your S185 will have some issues after using it for some time. The most common Bobcat S185 problems are malfunctioning controls, fuel system issues, problematic steering, axle issues, and loss of hydraulic power.

Does your Bobcat S185 break down from time to time? Join us as we discuss issues affecting this loader and practical solutions.

Contents

Malfunctioning Joystick Controls

Bobcat S185 operators claim that the joystick controls become unresponsive from time to time. Issues with the loader’s controls can occur due to improper maintenance, poor handling, or regular wear and tear.

The possible causes of malfunctioning controls in your loader are:

- Loose or disconnected control connections

- Frayed or damaged wires

- Worn or damaged push buttons

- Damaged joystick controls

Effective Solutions:

If the joystick controls fail to respond in any direction, examine the push buttons for physical damage or wear. Replace them if they won’t work due to wear or damage.

Then check if there are loose or disconnected connections to the joysticks. Disconnect and clean the connections to remove dirt, corrosion, or grease. Reconnect and tighten all connections.

Next, examine the wiring from the hydraulic pump and the actuators to the joysticks. If you find frayed or broken wires, replace them. You can also use a multimeter to determine the problematic cables or connections.

If the Joystick controls are still unresponsive, consider replacing them. A professional specialist will help replace the entire component.

Loss of Hydraulic Power

This skid steer loader relies on the hydraulic system to move the arms and bucket when lifting loads. Unfortunately, poor maintenance and improper handling can cause the loader to lose hydraulic power.

Your loader can lose hydraulic power due to the following:

- Hydraulic pump failure

- Cylinders failure

- Clogged hydraulic filter

- Leaking hydraulic fluid

Fixes:

Examine the hydraulic system to ensure there are no leaks. Fluid leakage can result from loose connections or defective seals, gaskets, or pipes. Secure loose connections and replace worn or broken seals, gaskets, and pipes.

If the power loss issue persists, inspect the hydraulic pump. A clogged pump won’t create pressure to supply hydraulic fluid. So remove the pump and give it a thorough cleaning. If you have a damaged pump, hire an experienced mechanic to repair or replace it.

A clogged hydraulic filter can block fluid flow, causing power loss. Remove the dirty filter and clean or replace it.

Inspect the hydraulic cylinders for defects. Damaged seals and leaky valves can cause the cylinders to fail. Replace these components if necessary. You can also replace deformed or damaged cylinders.

Bobcat S185 Axle Problems

One of the most reported Bobcat S185 problems is axle failure. Failing front and rear axles can result from poor maintenance and user-related errors. Some owners report that the axle clicks when using the steering lever.

Issues with the axles can cause your skid steer to pull to one side or fail to rotate the tires. This problem often occurs due to damaged bearings, leaking seals, and low lubricant.

Effective Solutions:

Jack up your skid steer and remove each wheel to examine the axles. Loosen the bolts to disassemble the hub. Access the bearings and seals to inspect them for damage. If you find broken bearings or leaking seals, replace them.

Then inspect if oil leakage causes the tapers to slip. Clean the oily tapers to ensure they grip properly. After reassembling the axle, ensure the bearings receive adequate lubricant to prevent them from breaking.

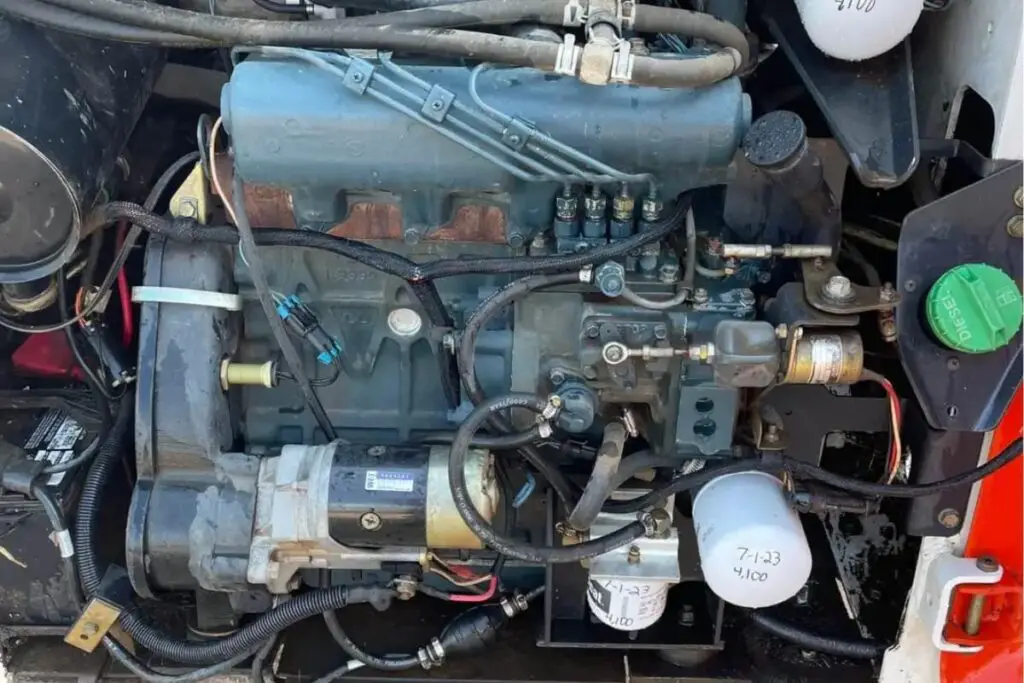

Fuel System Issues

The fuel system in Bobcat S185 is prone to several issues that can affect the loader’s performance. If your S185 has problems with the fuel system, you might experience symptoms like difficulty starting, power loss, misfires, and engine stalling.

Fuel system problems can result from the following:

- Contaminated fuel

- Malfunctioned fuel pump

- Clogged fuel filter

- Leaks in the fuel lines

Fixes:

Start by checking the condition of the fuel in the tank. If the fuel looks dirty, cloudy, or dark, drain it and add fresh fuel. Then examine the fuel lines to spot leaking areas. Tighten loose connections and hire a specialist to repair or replace leaking parts.

If fuel doesn’t flow into the cylinders, check for clogs in the lines. Clean the lines to remove debris or residue and replace a clogged filter.

Lastly, examine the fuel pump. The pump can fail due to clogs, electrical faults, wear and tear, or damage. Clean the pump and secure loose electrical connections. If the pump looks excessively worn or damaged, replace it.

Battery Failure

The battery is the power source that supplies voltage to various electrical components of your loader. If the battery and its components fail, your Bobcat S185 might have starting difficulties. Electrical components such as lights and controls might also malfunction.

Like most Bobcat S185 problems, battery failure can result from improper maintenance or poor handling. The following issues can cause your loader’s battery fails:

- Clogged terminals

- Loose terminal connections

- Broken terminal clamps

- Insufficient electrolytes

Effective Solutions:

Check the battery to ensure it’s in prime condition. If the terminals and connections appear clogged, use a wire brush and hot water to remove the corrosion. Tighten the loose terminal connections to ensure the battery charges and supplies voltage as required.

If your battery has broken terminal clamps, take it to a specialist to replace the clamps.

Low battery voltage can cause electrical components to malfunction. Use your multimeter to check the battery voltage and recharge it if necessary.

Check the battery’s electrolyte level and refill it as the manufacturer recommends. If the battery fails to accept a charge, replace it.

Problematic Steering

The power steering in Bobcat S185 can fail over time and make it difficult to steer the loader. Besides difficulties navigating, you might experience other symptoms like strange noises while steering, jerky steering, or fluid leaks from the system.

The most common causes of power steering failure in this loader are:

- Malfunctioning steering pump

- Contaminated steering fluid

- Damaged or loose steering belt

- Damage or worn-out steering cylinder

Solutions:

Check for low or contaminated steering fluid if the power steering is unresponsive. Refill the reservoir if necessary and change the fluid if dirty or contaminated. Then examine the steering system to see if there are leaking parts.

In most cases, a damaged or worn steering cylinder can cause the fluid to leak. Allow a professional to repair or replace the steering cylinder. The professional can also assess the steering pump’s condition and repair or replace it.

Inspect the steering belt to see if it appears misaligned, loose, worn, or damaged. Tension the belt properly to ensure it transfers power efficiently. Replace the belt if worn or damaged.

Are Bobcat S185 Problems a Deal Breaker?

The S185 from Bobcat rivals other high-quality skid steer models when it comes to lifting capacity. While this loader develops problems over time, you can rest assured of a versatile and reliable machine.

You can address common Bobcat S185 issues if you’re a DIY enthusiast. Alternatively, a professional technician can help you resolve the challenging issues. Once your loader is up and running, consider proper maintenance and handling to ensure it’s functional for a long time.

Hello! My name is Chris, and I am the founder of Yard Floor. When I was a toddler, my family had a lush green lawn. I was at the center of caring for and maintaining this lawn and even proceeded to take an associate’s Degree in landscaping. I am here to share my years of experience with you – be it repairing your mower/tractor or caring for your lawn.